Renova

RENOVA – TORRES NOVAS – PORTUGAL

Plant Expansion Project

TEE has been awarded the project execution for the New Paper Machine 7 Project at Renova Tissue Paper Mill, in Torres Novas, Portugal.

TEE’s project involved the Basic and Detail Engineering as required for the installation of the new PM7 Machine.

TEE was in charge of the Renova mill lay-out modifications; the PM7 foundations and building design, the electrical and safety design, as well as the design of the piping and E&I interfaces between the new machine and the existing mill.

The project involved also the design of a new fully automatic warehouse for finished goods. TEE’s activities included also all the licensing work, the procurement, including the procurement for the erection on the machine and the site supervision.

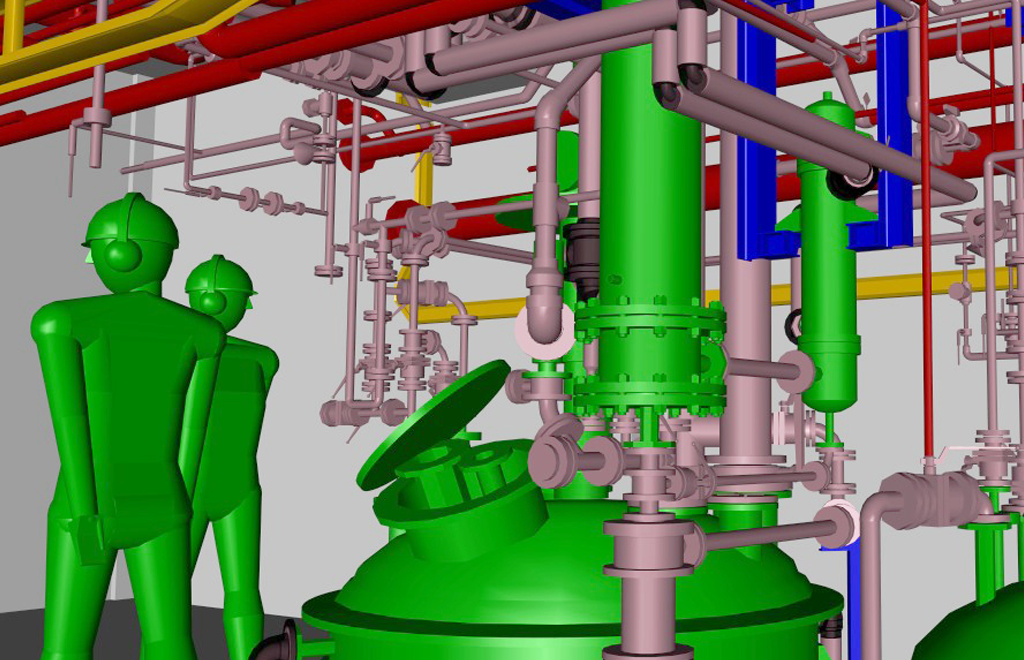

The entire project was developed using TEE’s integrated 3D project development tools. These systems were fundamental for the project success as they enabled a seamless project integration with the PM7 machine supplier and made possible the complete project coordination and design review at TEE’s home office.